Machine Type:

Pre-Extruders

Machine Type Filters

FILTER

Pre-Extruders

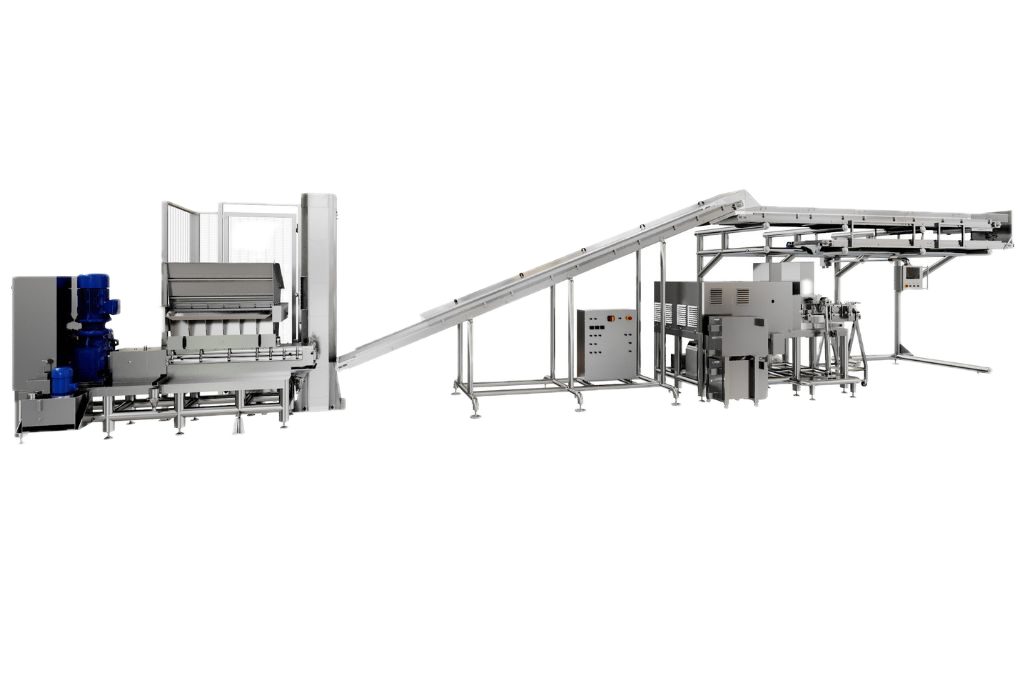

Pre-extruders play a key role in chewy and gum production process.

It’s designed for the automatic feeding of the final forming extruder by processing masses through a temperature-controlled chamber and then through the extruder head.

The result is a continuous rope or sheet of mass (depending on the application), homogeneously distributed and stabilized at the correct temperature for all downstream operations.

Our Models

070PR Pre-Extruder