Machine Type:

Extruder and Co-Extruders

Machine Type Filters

FILTER

Extruder and Co-Extruders

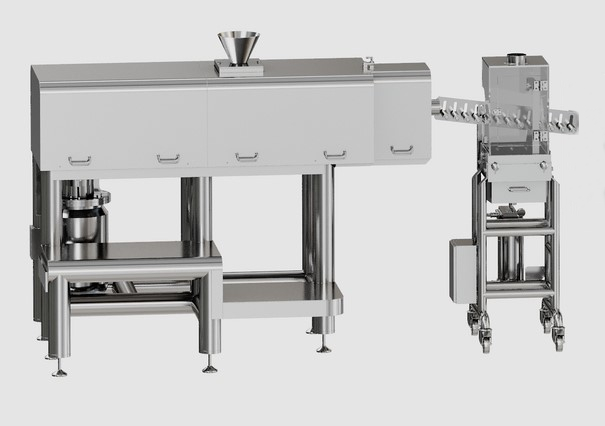

Nuova Euromec extruders are designed to manage different confectionery masses with efficiency and precision:

Crystallized chewy masses: require extrusion since they are not malleable at their starting temperature (typically 35–45°C before loading). The same applies to gum masses.

Hard-boiled masses: extrusion is less common, but it is the perfect solution for striped products.

We also offer dual-unit extruders to process two-color or two-flavor masses of chewing gum, bubble gum, or chewy-toffee, feeding one or multiple cut & wrap machines or forming lines.

On this page, you will find a selection of our models, developed to meet the most common production requirements.

Our Models

236ES Flextruder

040ES Extruder for gum filling

141ES Striping extruder

223ES/247 Co-Extruder

220ES Extruder