Machine Type:

Cooling Tunnels

Machine Type Filters

FILTER

Cooling Tunnels

Cooling tunnels represent the final stage of our production lines, with specific functions depending on each line’s production goals. Their primary role is to reduce the temperature of the product after forming, preparing it for packaging, while maintaining its shape and removing potential scraps.

Applications include:

Cooling gum or chewy ropes and preparing them for feeding into cut & wrap machines or chewy candy center sheets

Cooling hard candies (sugar and sugar-free), caramels, chewy products, and chewing gum

Cooling ball lollipops to prevent shape deformation

Cooling both spherical and flat lollipops, or hard-boiled candies, within the same tunnel

Tunnel dimensions and configurations vary according to the required production capacity.

Our Models

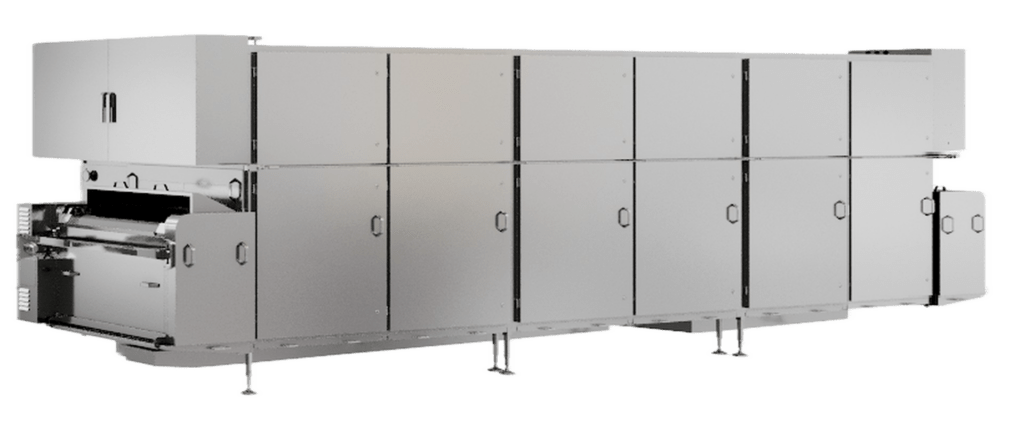

222TR Cooling tunnel for hard candy, soft candy, flat lollipops and gum.

129TRH Cooling tunnel for ball lollipops

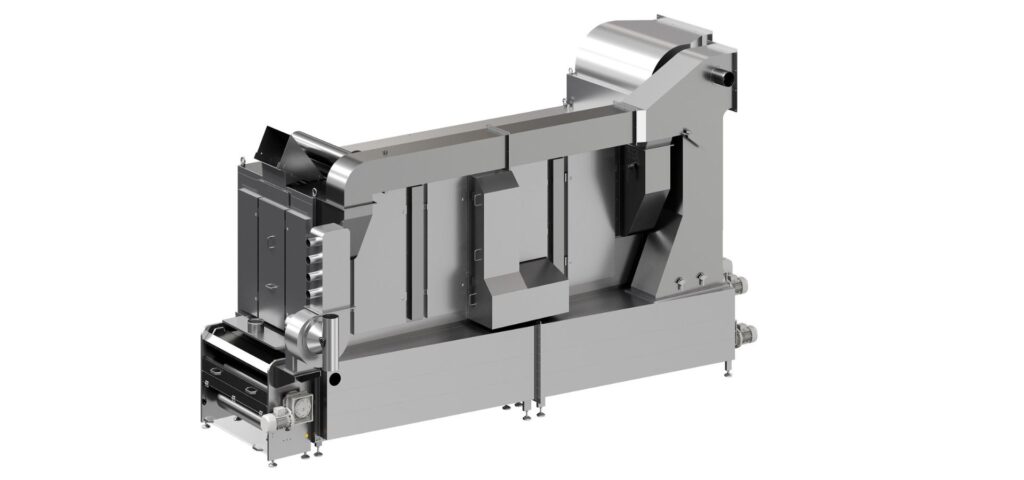

068TRD Cooling tunnel for chewy candy

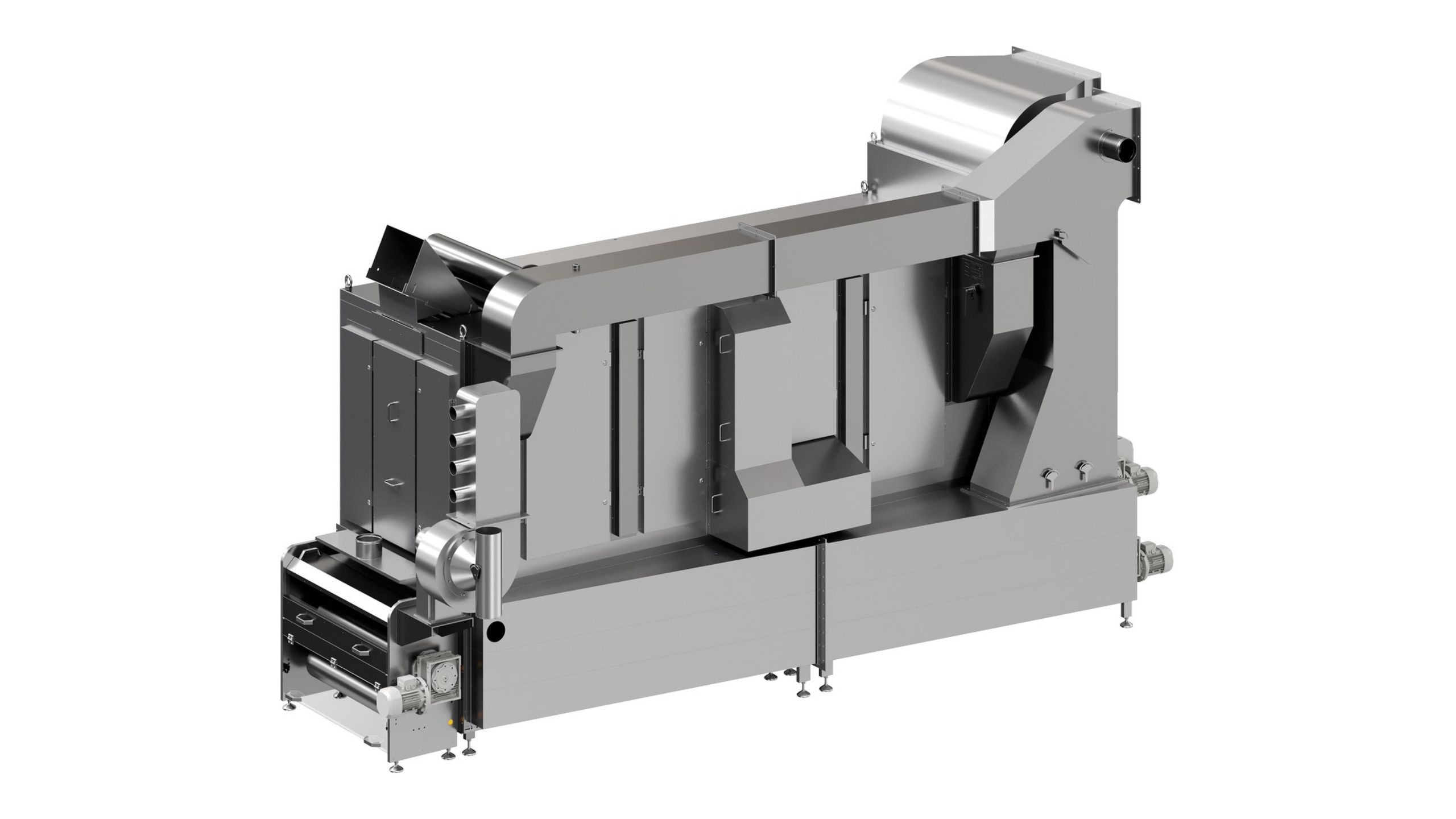

138TRH Universal cooling tunnel for candy, flat lollipops and ball lollipops