Machine Type:

Chain Formers

Machine Type Filters

FILTER

Chain Formers

The forming machine is the core of the production process: it is where the chain die sets are installed and where each candy takes its final shape. Nuova Euromec forming machines are engineered to work with our latest-generation die sets, optimized for the application of liquid, powder, or gum fillings ranging from 10% to 40%, depending on the product.

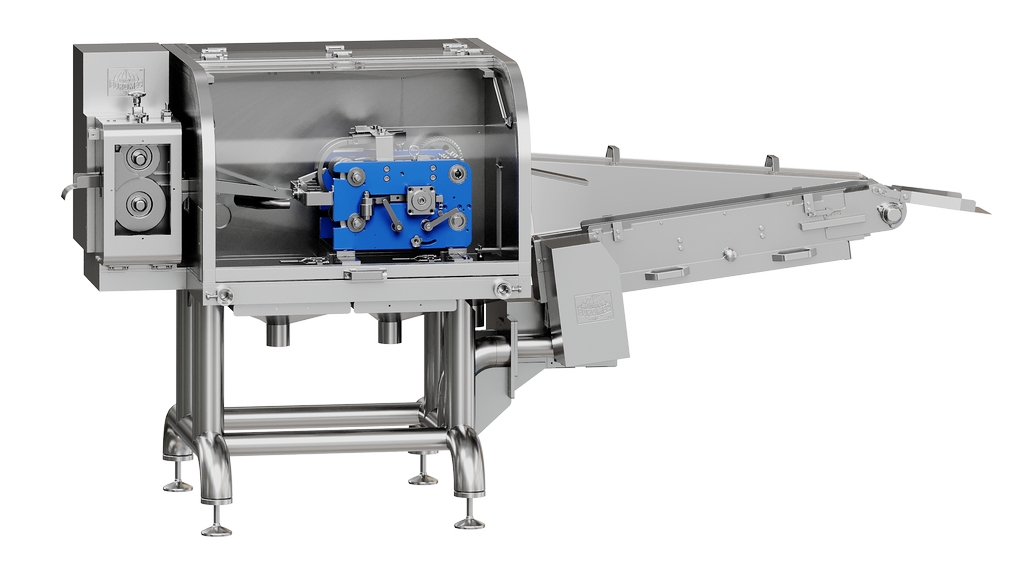

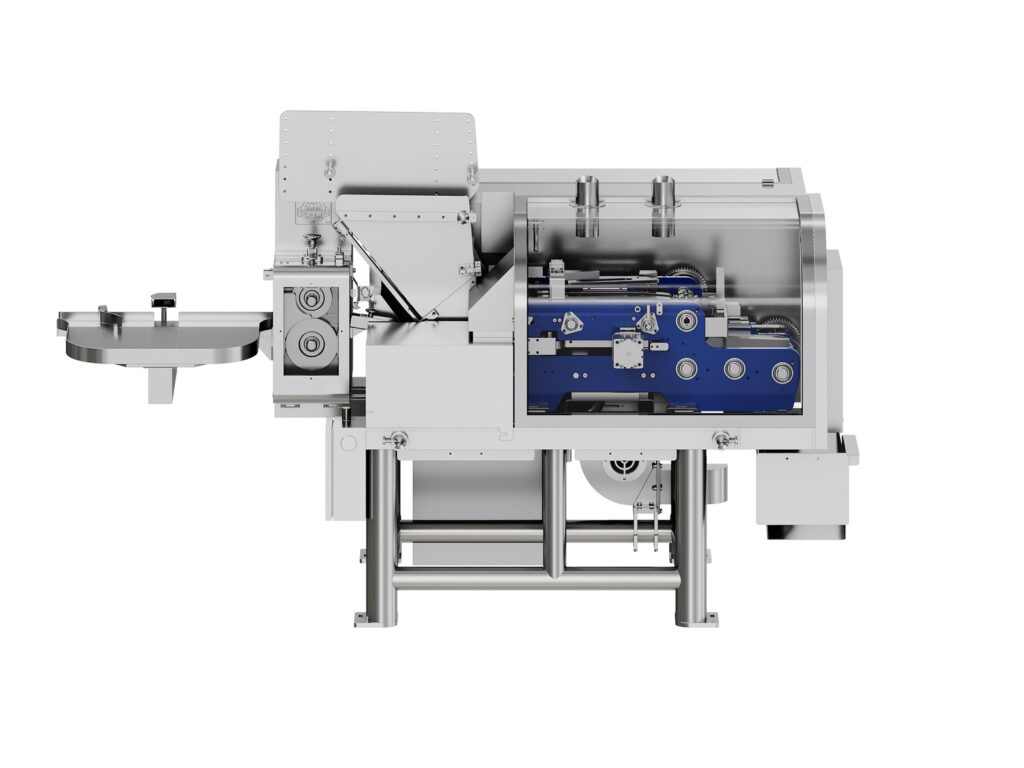

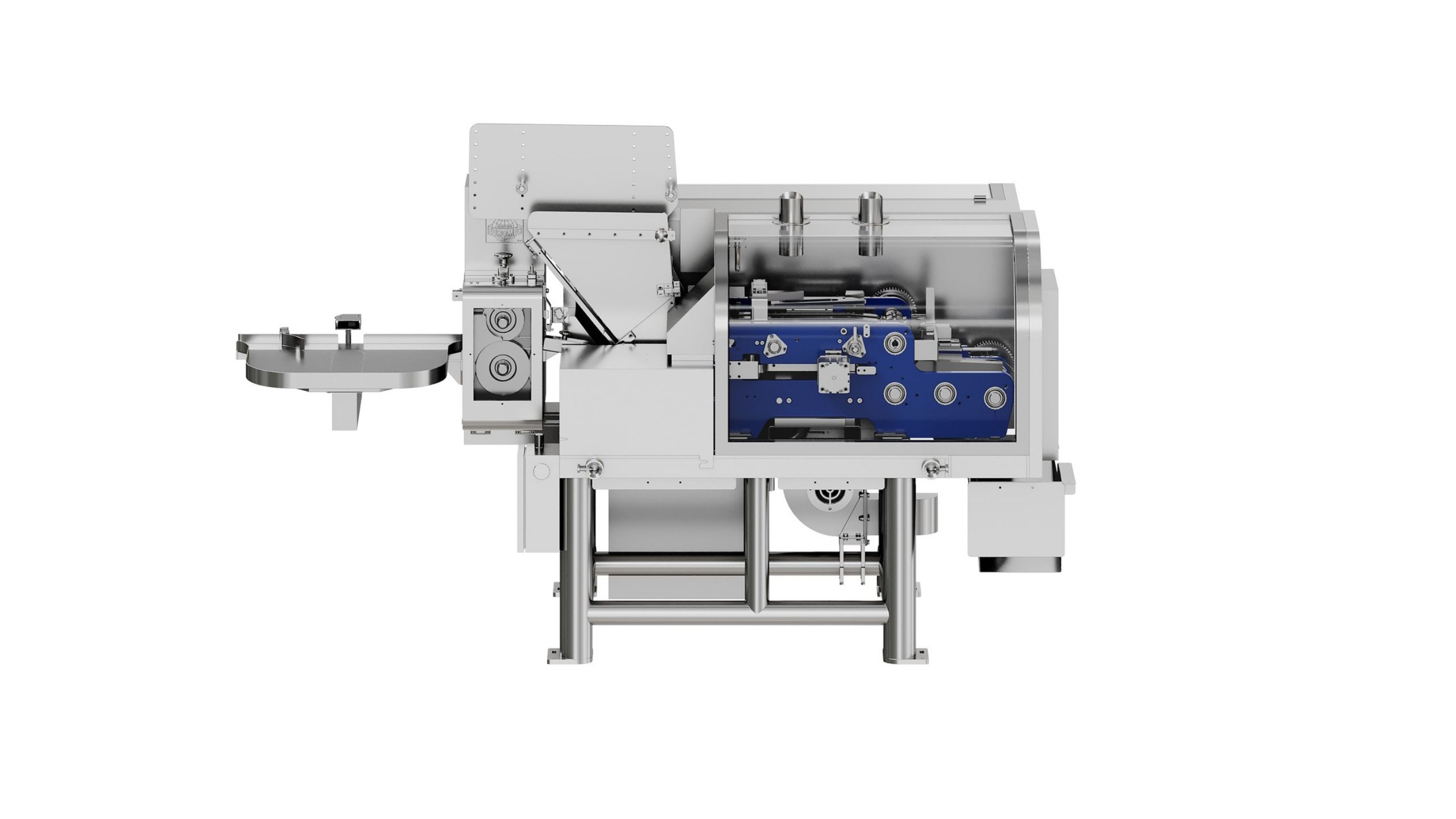

We provide two main models to cover different production needs: the 190MC forming machine, designed for hard candy, chewy candy, filled gums, and lollipops, and the 174MC forming machine, built for high-speed production of hard-boiled and high-percentage filled candies.

Our Models

174MC Chain Former

190MC Chain former