Machine Type:

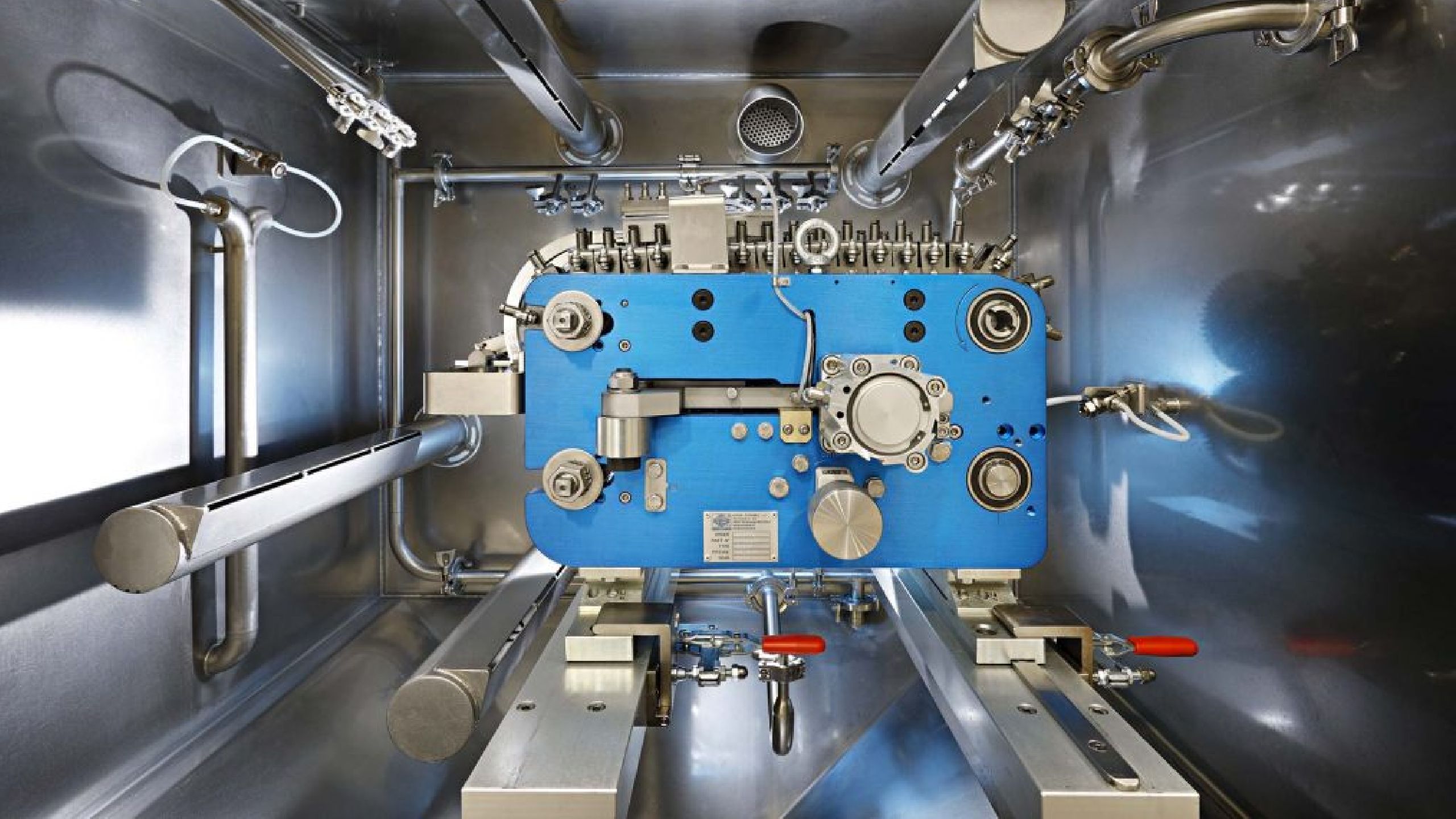

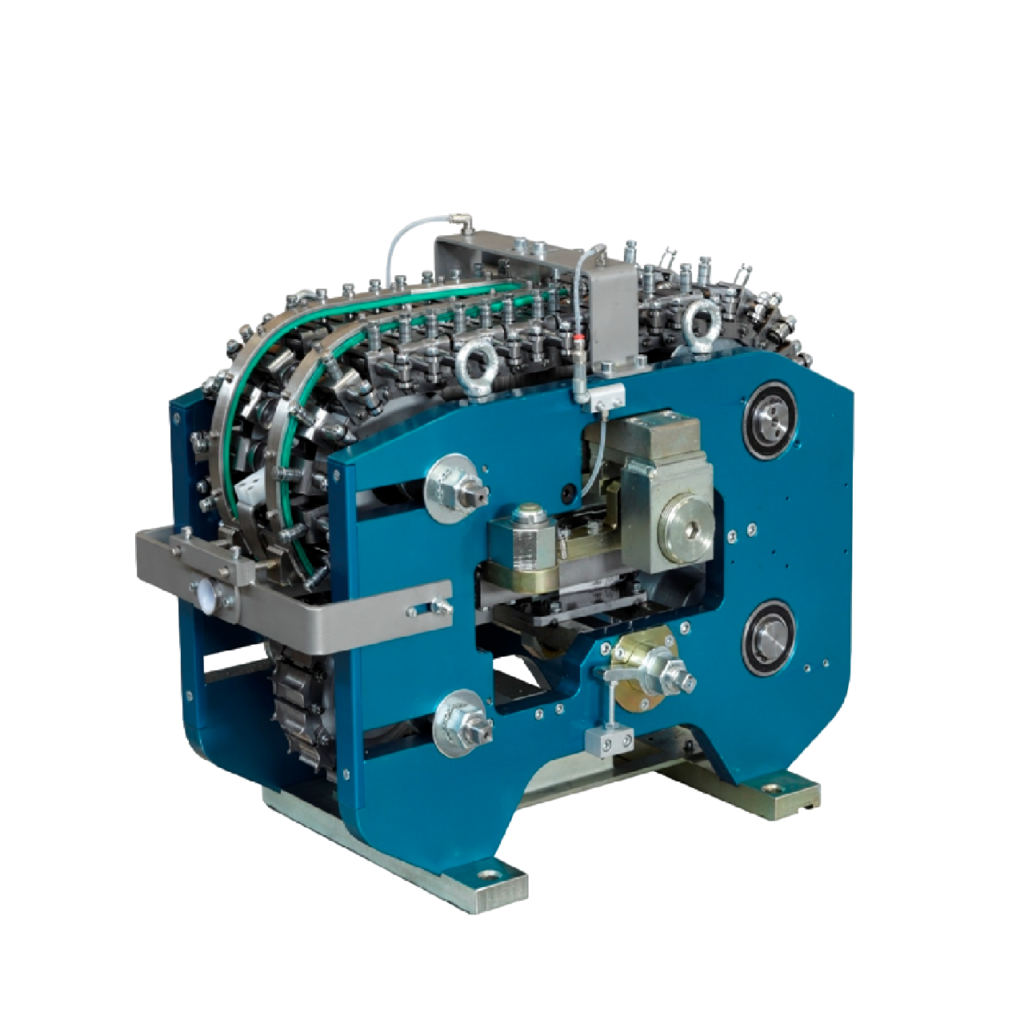

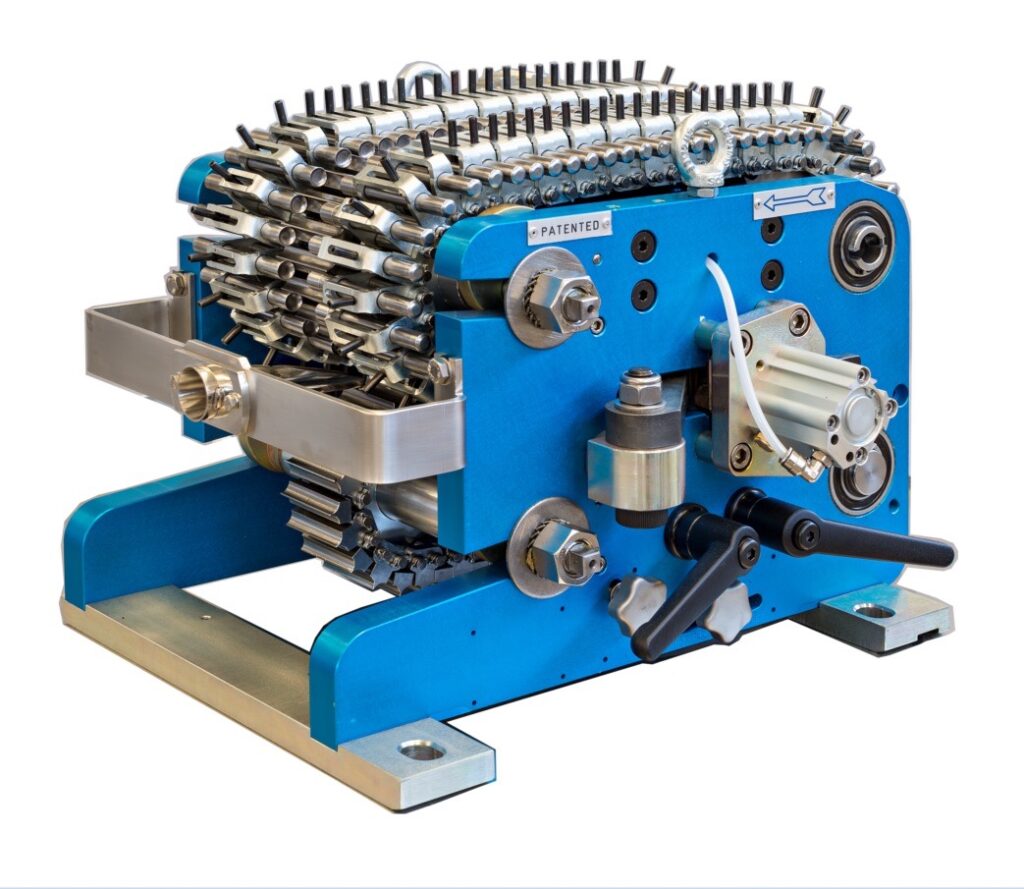

Chain Die Sets

FILTER

Chain Die Sets

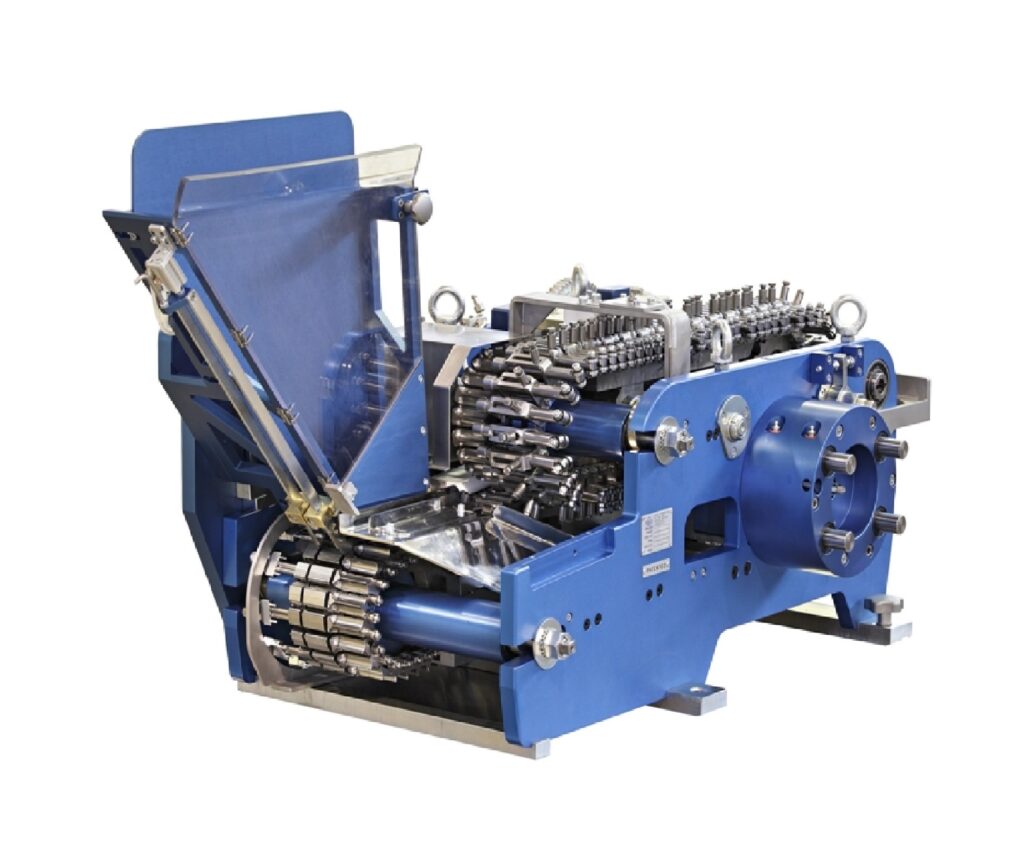

Die forming is one of the fundamental steps in any confectionery production line. Within the industry, two forming systems are the most widely used: chain die sets and rotary die sets, each with unique features. Chain die set technology is recognized as the most efficient, flexible, and versatile solution for producing high center-filled candies.

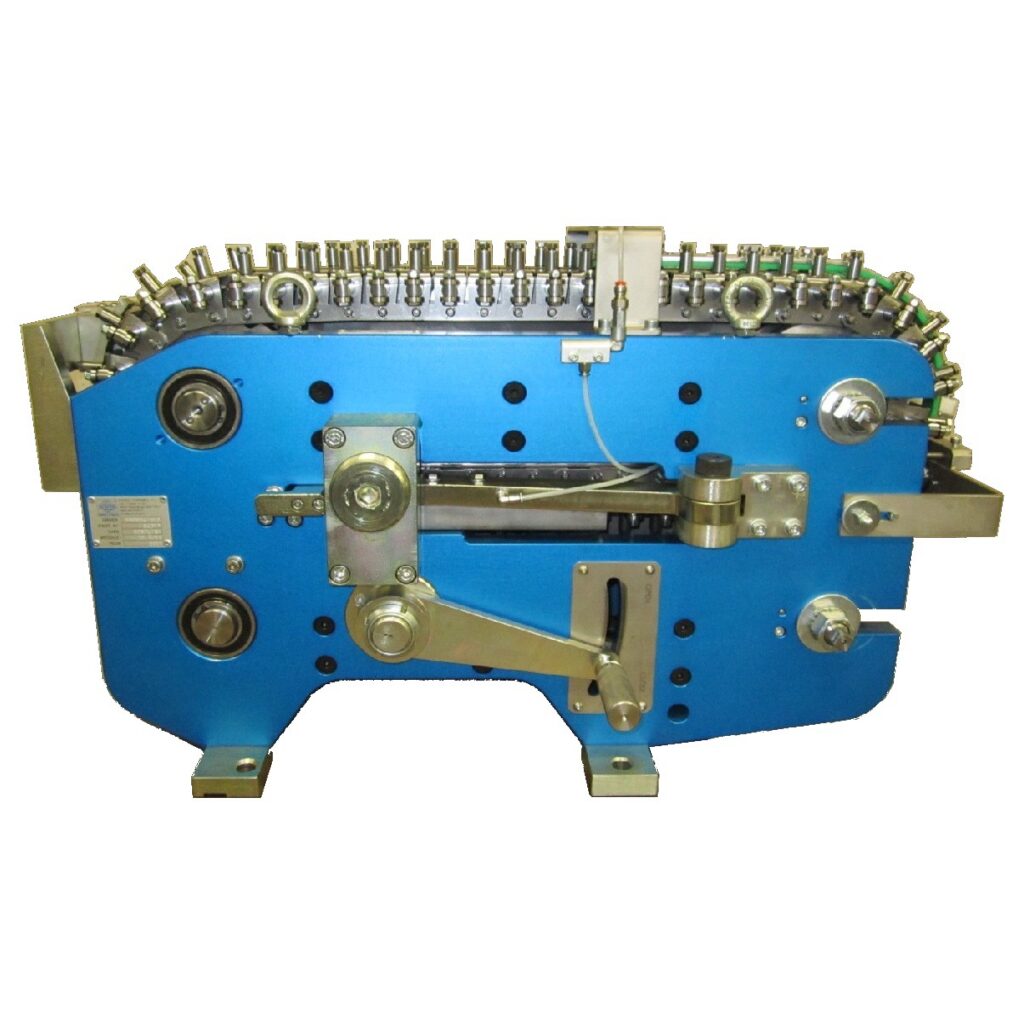

A chain die set is the format part of the forming machine, where the candy takes its final shape. It defines the size, design, and weight of the finished product while also setting the production rhythm. As a result, the quality of the die set directly impacts the quality of the candy itself.

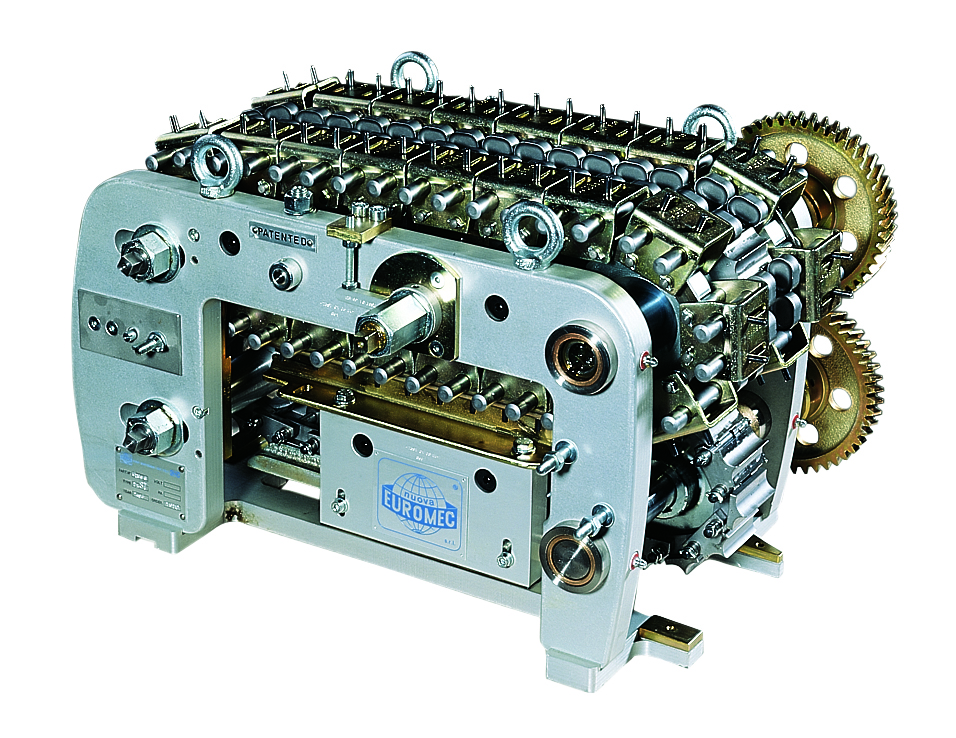

Nuova Euromec’s story began in 1952 with the design and production of chain die sets for hard candy and filled candy lines. Since then, we have earned international recognition for the performance and durability of our die sets. And this is no coincidence.

Over the decades, we have developed a dedicated department for the in-house manufacturing of die punches and spare parts. With advanced CNC machines operated by highly skilled specialists, we deliver complex, precise, and durable solutions in the shortest possible time.

Every Nuova Euromec die set is custom engineered according to the customer’s specifications and built using food-grade, hardened materials, ensuring long-lasting reliability and consistent performance.

Choosing Nuova Euromec chain die sets brings clear advantages for confectionery producers:

– Unmatched product quality: consistent shape, weight, and surface finish with every piece.

– Faster time-to-market: thanks to our in-house design and production capabilities.

– Reduced downtime: durable materials and precision manufacturing extend service life and minimize maintenance.

– Full customization: every die set is tailored to customer-specific designs and product requirements.

– Reliable investment: long-lasting performance ensures lower total cost of ownership.