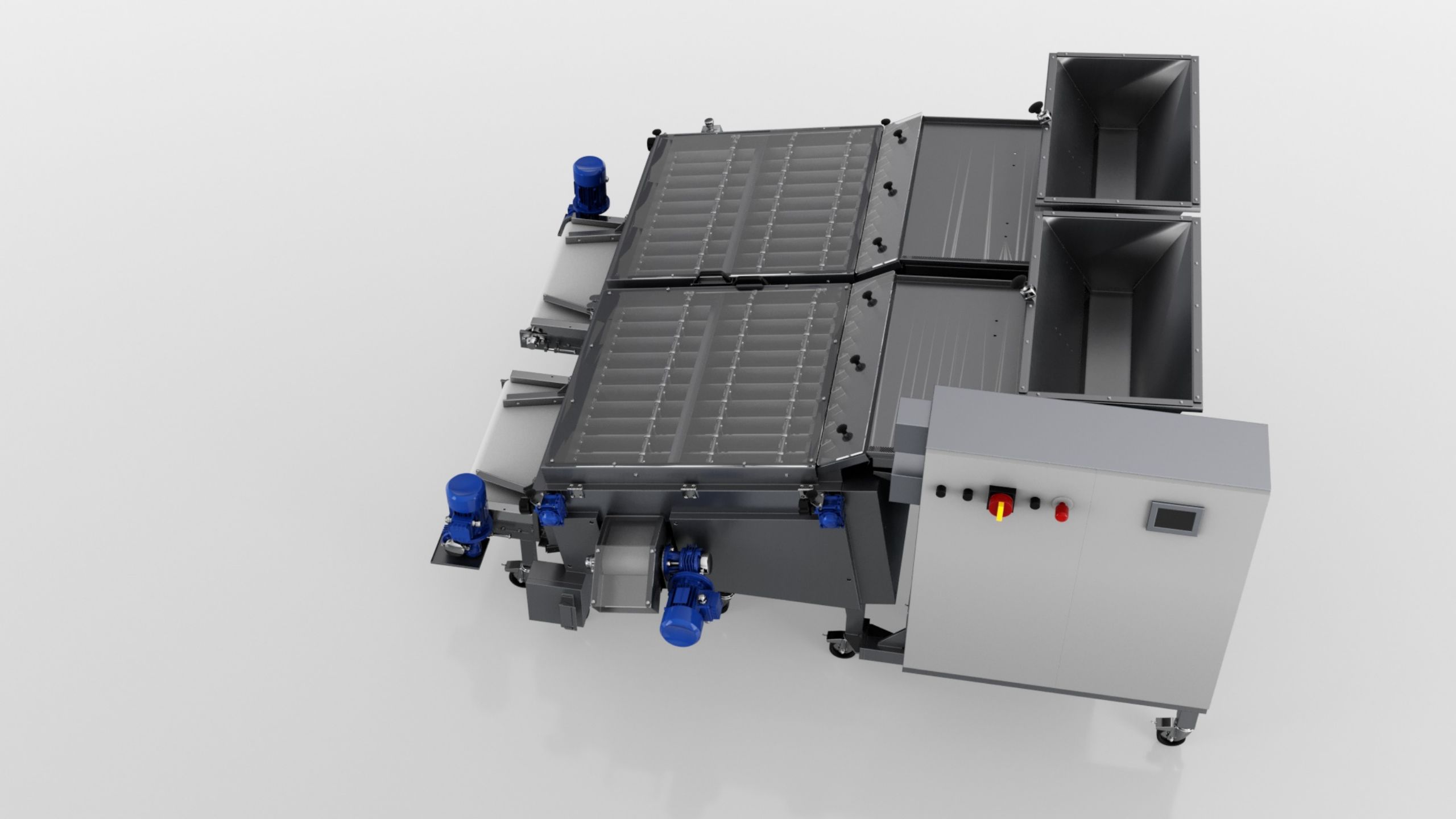

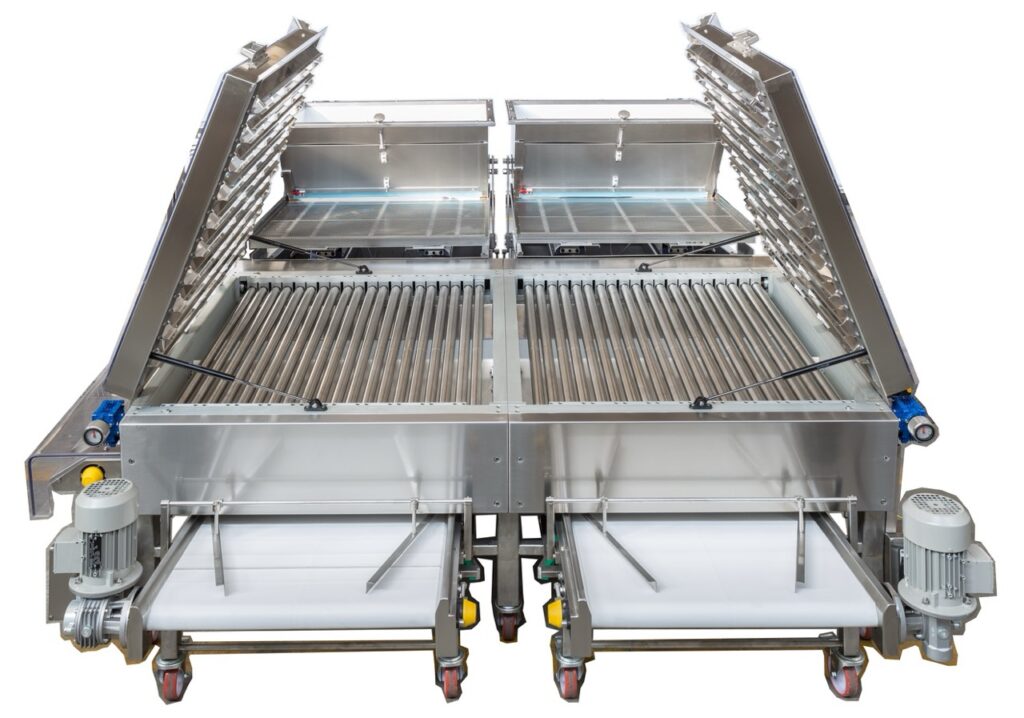

101CAC Calibrating machine

The sorting process is carried out by rollers. The rollers are protected by a safety cover equipped with a switch, ensuring safe operation.

The system separates products into three categories:

- Too thin – undersized products, broken pieces, or deformations.

- Good – products with the correct and uniform thickness.

- Too thick – oversized products, twins, triples, or deformations.

Correctly sized products can be discharged either straight in-line to feed the wrapping machines or metal detector or to the side for collecting box and manual handling, according to customer requirements.

Performance is ensured by:

- Infinitely adjustable product flow speed via an electronic speed regulator.

- Brakes and dampers to control product movement, preventing overlap that could affect sorting accuracy.

- Hand-wheel adjustment of the rollers distance (sorting tolerance) from 2 to 15 mm, with no tools required for product thickness changes.

- Sorting accuracy of ±0.050 mm up to ±0.500 mm, defined at the time of order and technical specification agreement.

The machine performs best at 55% relative humidity and a temperature of 18–20°C (65–68°F). Designed in full compliance with EC regulation 89/392/EWG, it guarantees safety, reliability, and consistent results.

Our portfolio includes different sorting capacities ( according to product size and shape) from 25.000 pieces/hour up to 650.000 pieces/hour.