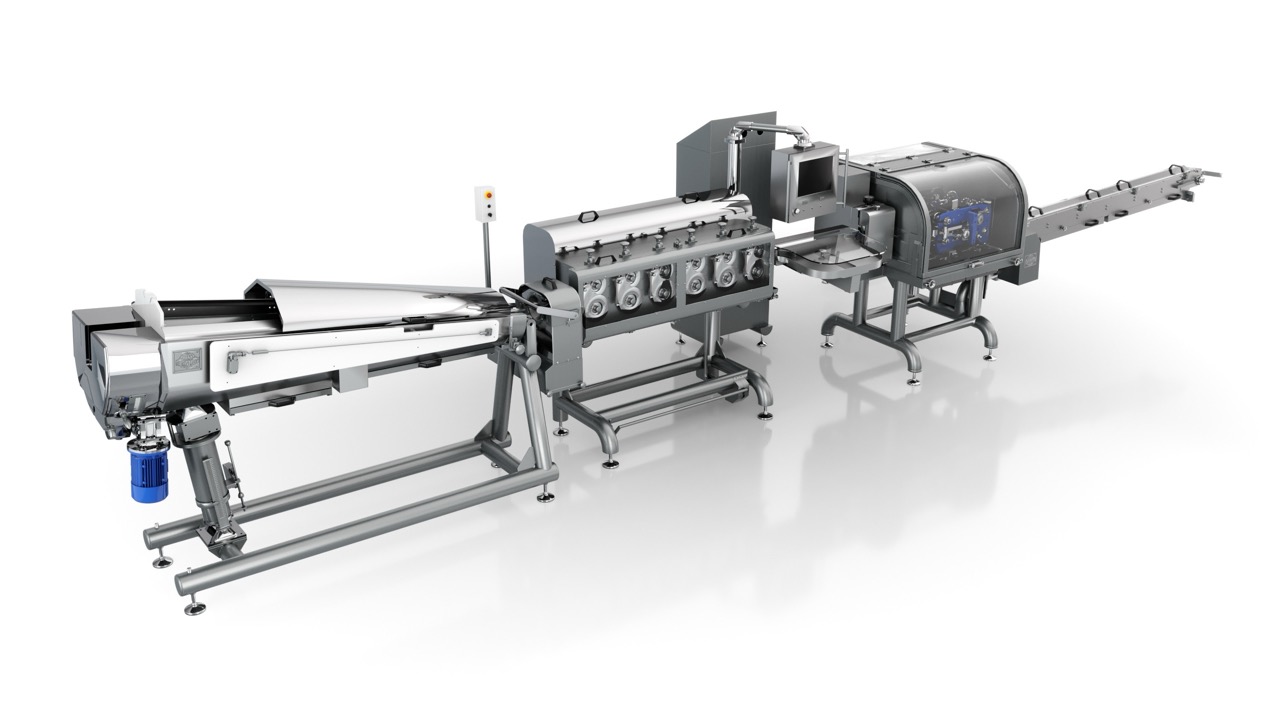

Y Flexible chain forming line for candies and lollipops

Y Flexible chain forming line for candies and lollipops

In the confectionery industry, flexibility is often just a slogan. At Nuova Euromec, it has become a defining feature of our technology. Our tailor-made flexible lines are built to adapt quickly, and the Y Line is the best expression of this approach.

On our Apollo-Explorer, S38, and S40 lines, a chain die set changeover takes less than five minutes, making it possible to switch between different shapes of the same product—for example, from a round to a square hard candy. With the Y Line, we took this concept further: why not switch between entire product categories in the same amount of time?

The Y Line combines the strengths of the S38 Line and the Apollo-Explorer Line, enabling the production of three distinct product categories on a single line. This is achieved through a new-generation forming machine capable of handling candy die sets, 3D and flat lollipop die sets, and ball lollipop die sets.

To ensure perfect cooling for every product type, the Y Line is equipped with two dedicated cooling tunnels placed side by side: one designed for flat and 3D lollipops and candies, and the other specifically for ball lollipops.

This configuration delivers clear advantages: space saving, energy efficiency, reduced labor needs, and a drastically lower investment cost compared to the purchase of multiple standalone production lines. All of this while preserving high performance, product quality, and maximum versatility with multiple color and filling combinations, fully adaptable to any cooking system, whether batch or continuous.