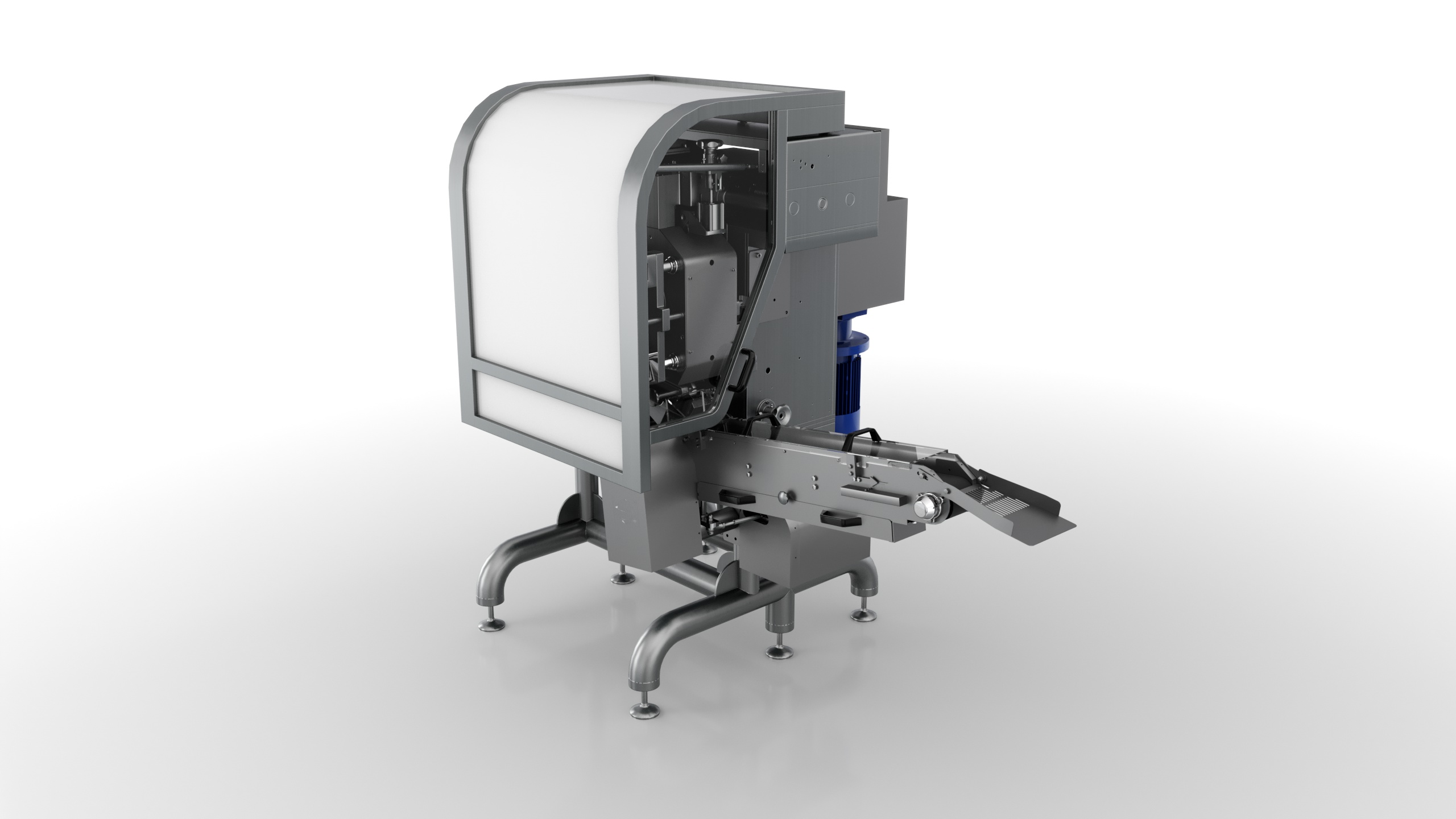

S31 – Rotary forming line for chewing gum

S31 – Rotary forming line for chewing gum

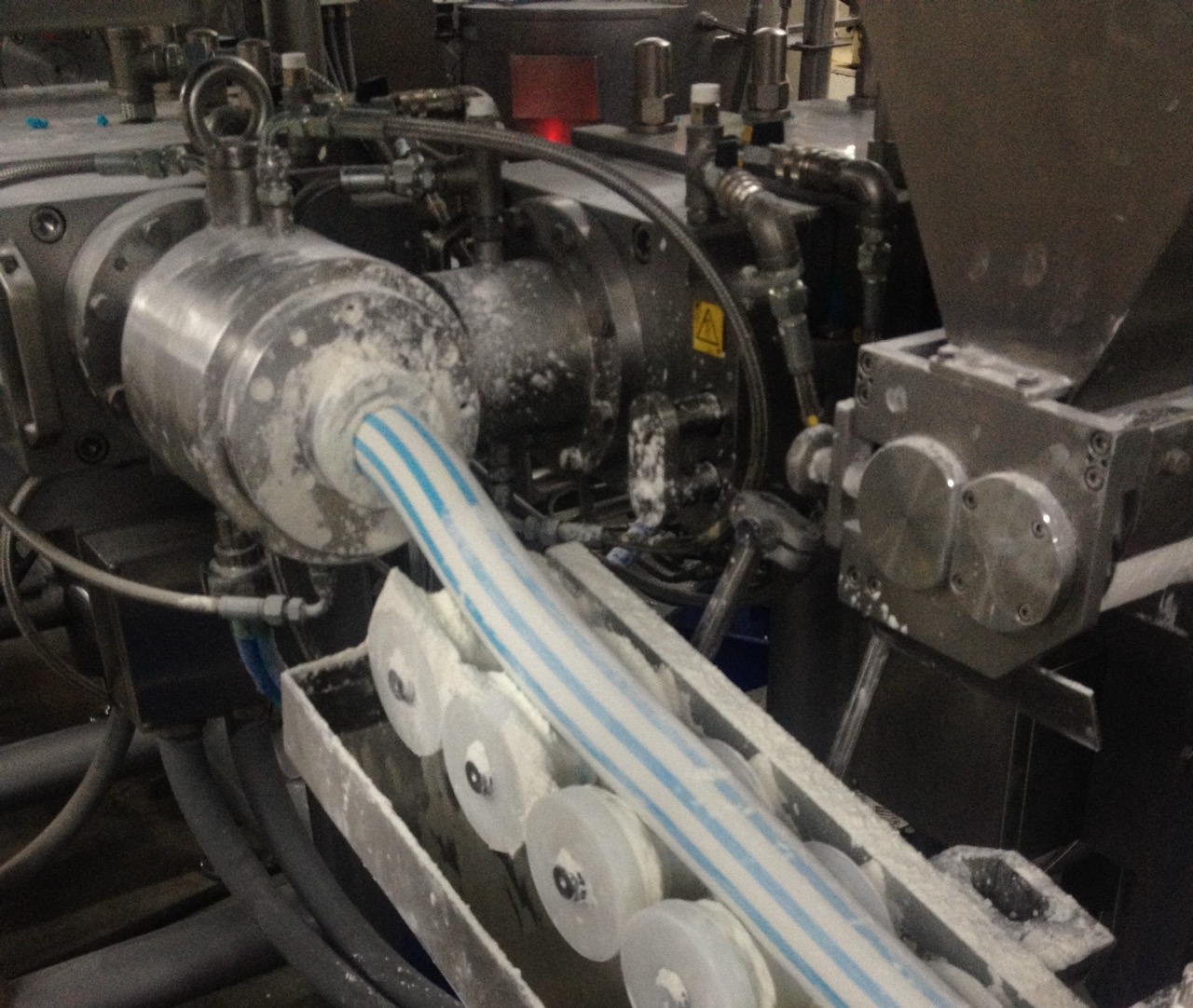

The S31 models stand apart from the Apollo Soft lines thanks to their extrusion based process instead of batch rolling.

This design makes the S31 ideal for the high speed production of die-formed gums. Extrusion technology also provides greater flexibility in product design, enabling the creation of striped and multicolored products. In addition, the die system makes it possible to include liquid fillings such as chocolate, syrups, or jams.

QUICK FACTS

Application

Chewing gum

Chiclet

PRODUCTION SPEED

300-1000 kg/h

Filling Options

Liquid

Color Option

1-4