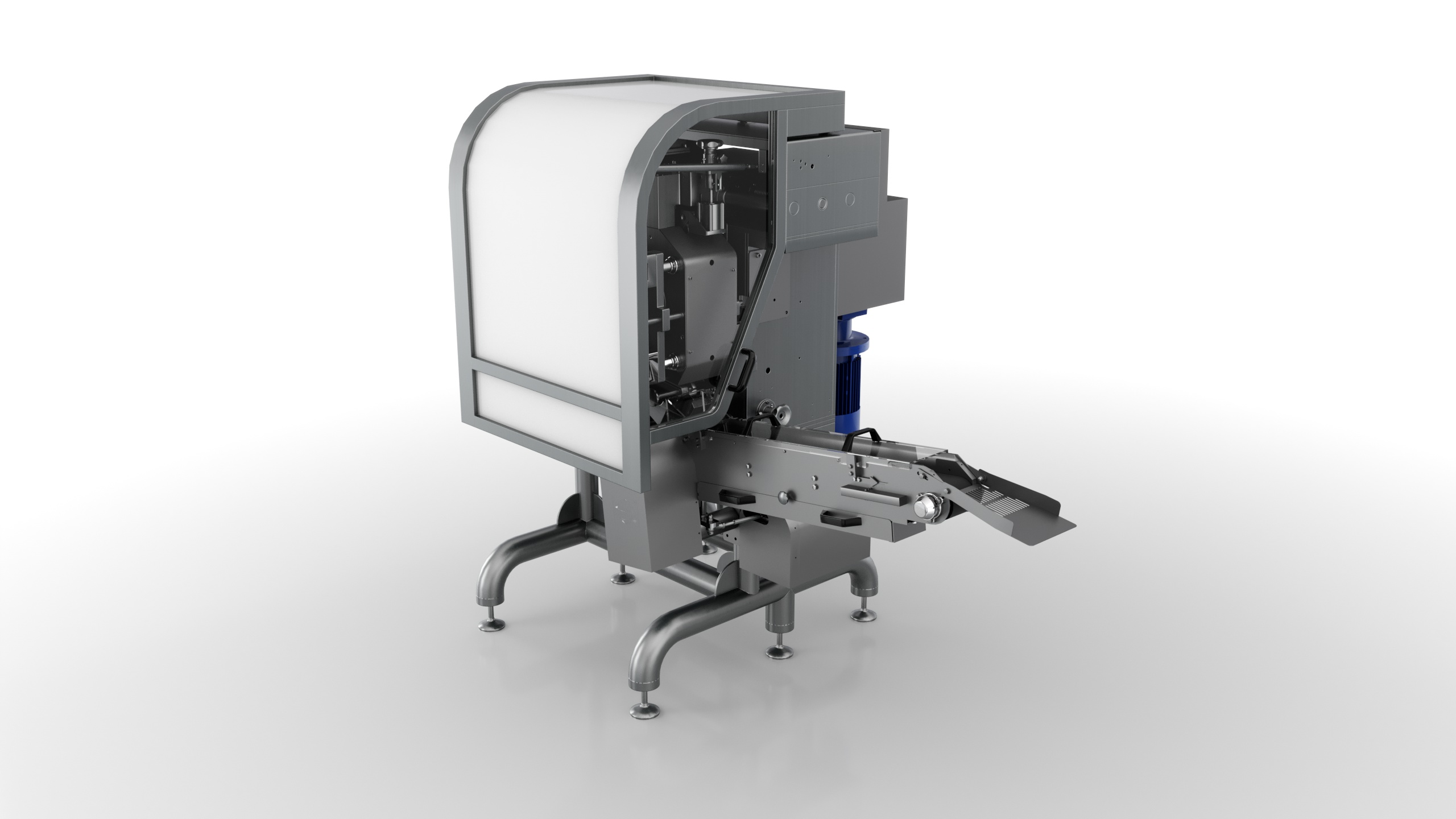

Mercury – Rotary forming line for hard candy

Mercury – Rotary forming line for hard candy

The Nuova Euromec Mercury line differentiates itself from the Apollo and Explorer lines due to its rotary forming machine, designed for continuous production environments where a wide variety of shapes or formats is not required, and for production with low filling percentage.

Our latest generation rotary forming machines maintain production speed, keeping quality standards, with exceptional consistency in shape, weight, and appearance, minimizing waste.

QUICK FACTS

Application

Hard candy

Lozenges

Medicated candy

Sugar free candy

Soft panned candy

PRODUCTION SPEED

300-1500 kg/h

Filling Options

Liquid

Powder

Gum

Chewy

Color Option

1-4