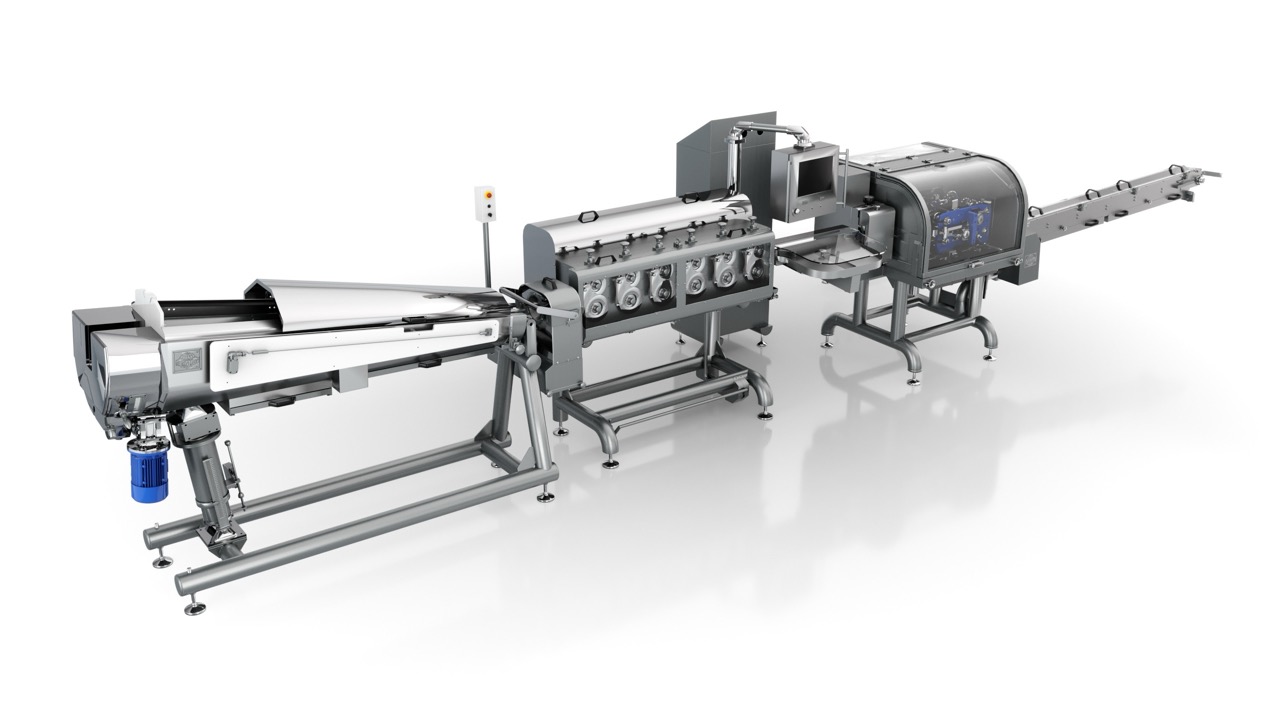

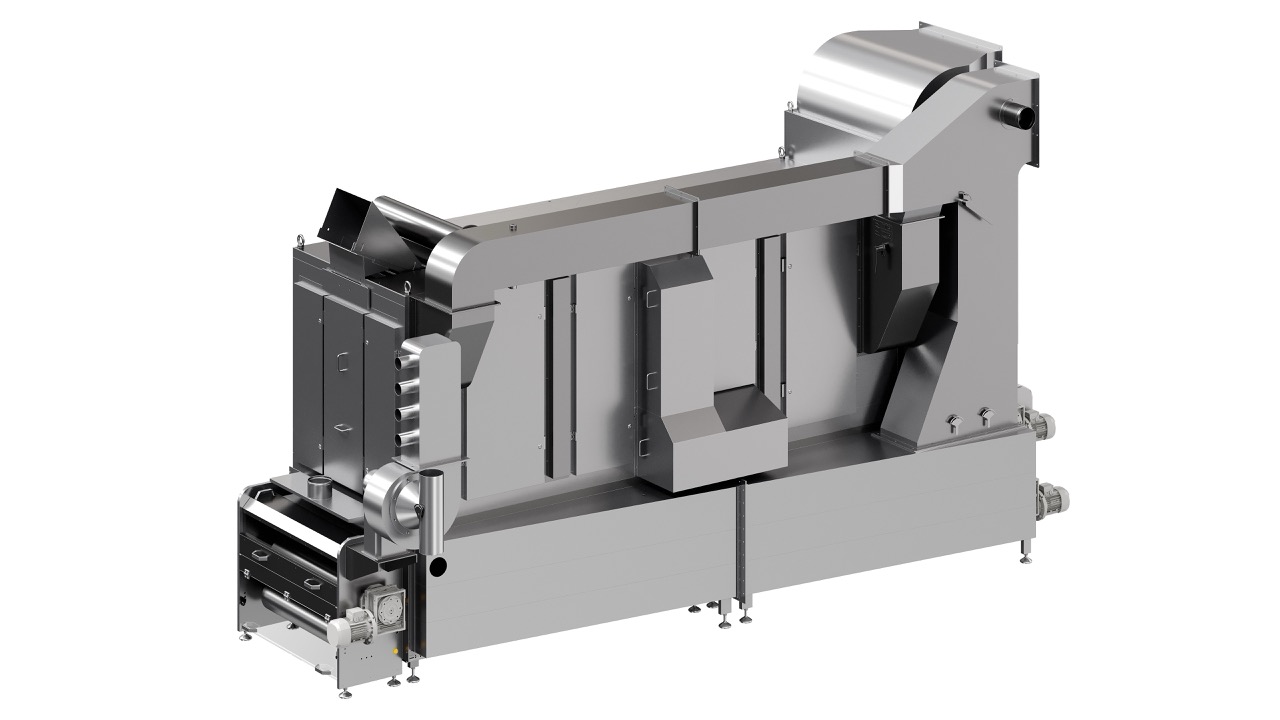

Flexible forming line with universal cooling tunnel

Flexible forming line with universal cooling tunnel

In the confectionery world, flexibility is often promised but rarely achieved. At Nuova Euromec, it has become a practical advantage built into our machines. Following the success of the Y Line, we created the Universal Cooling system, a solution tailored for manufacturers with flexible capacity demands or limited production floor space.

Designed as an evolution of our Apollo and S38 platforms, the Universal Cooling makes it possible to manage three product categories:

- Ball lollipops

- Flat lollipops

- Hard candies

All within a single line, combining efficiency with versatility.

The system provides measurable benefits: compact footprint, optimized energy consumption, lower manpower needs, and a reduced overall investment compared to installing multiple independent lines. At the same time, it guarantees the standards Nuova Euromec is known for, consistent performance, excellent product quality, and wide flexibility in color and filling combinations, with full compatibility across both batch and continuous cooking systems.