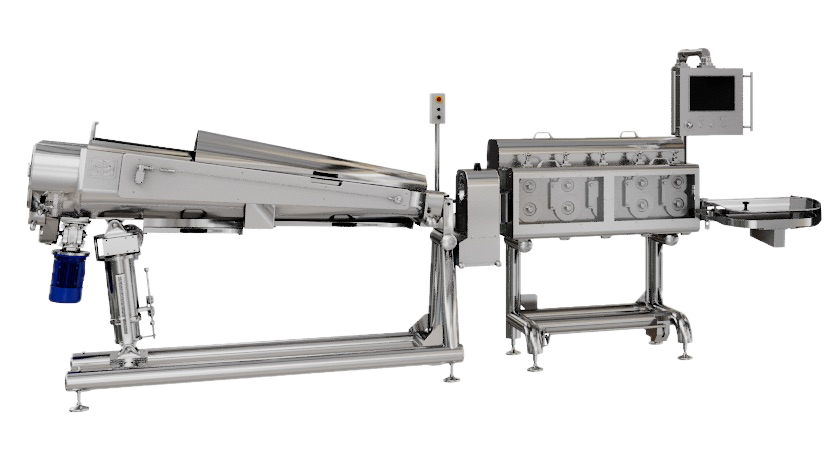

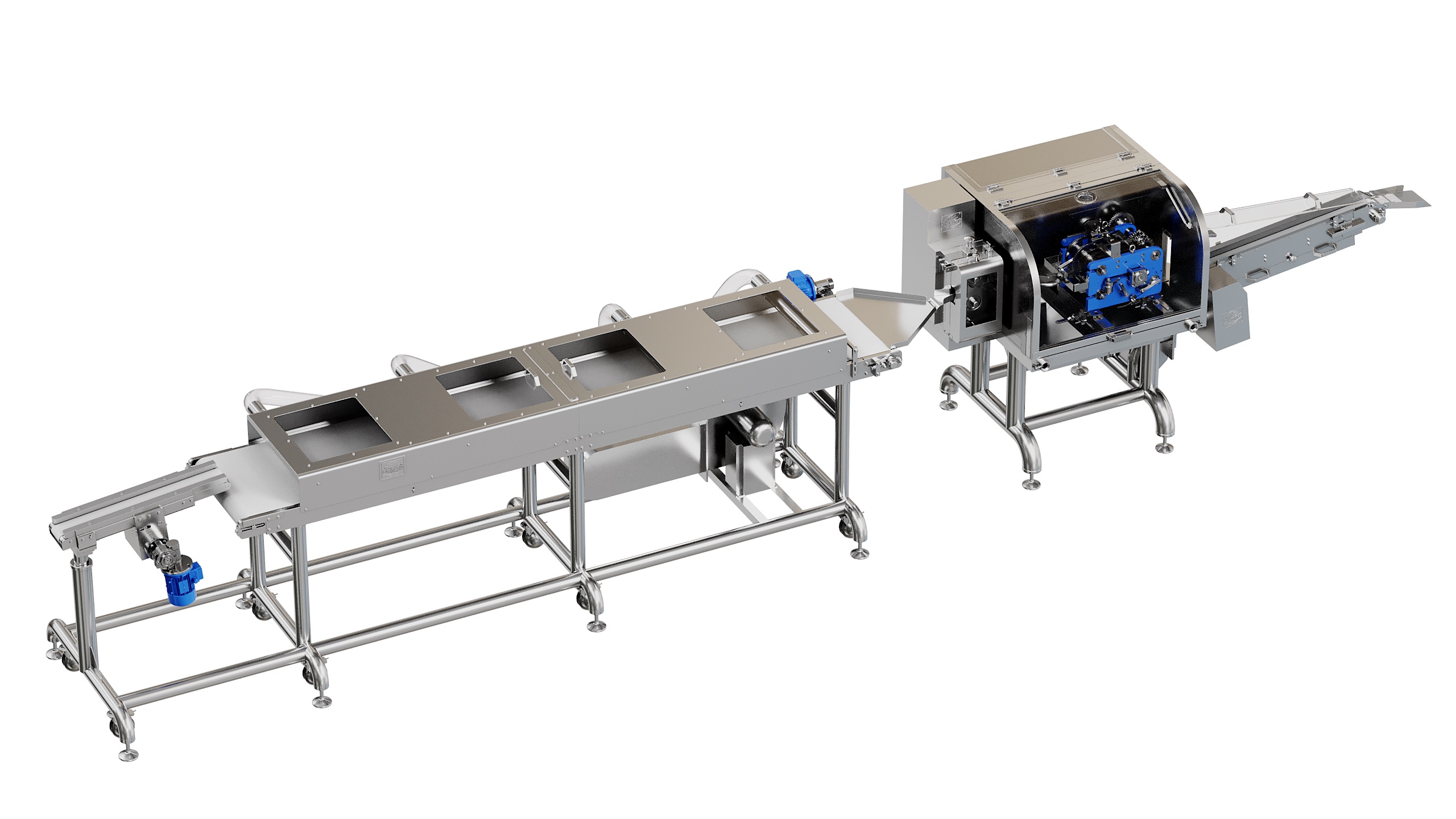

Apollo soft – Chain forming line for chewy candy

Apollo soft – Chain forming line for chewy candy

Apollo Soft is the Apollo version for chewy candies. Thanks to our last generation of chain die sets, this line is the perfect solution for producers of chewy and milk based candies with a high percentage of filling, who want a reliable, flexible, and durable line.

The forming machine has also been optimized for quick chain die set change, allowing fast production shift.

QUICK FACTS

Application

Toffe

Eclair

PRODUCTION SPEED

300-1000kg/h

Filling Options

Liquid

Powder

Color Option

1