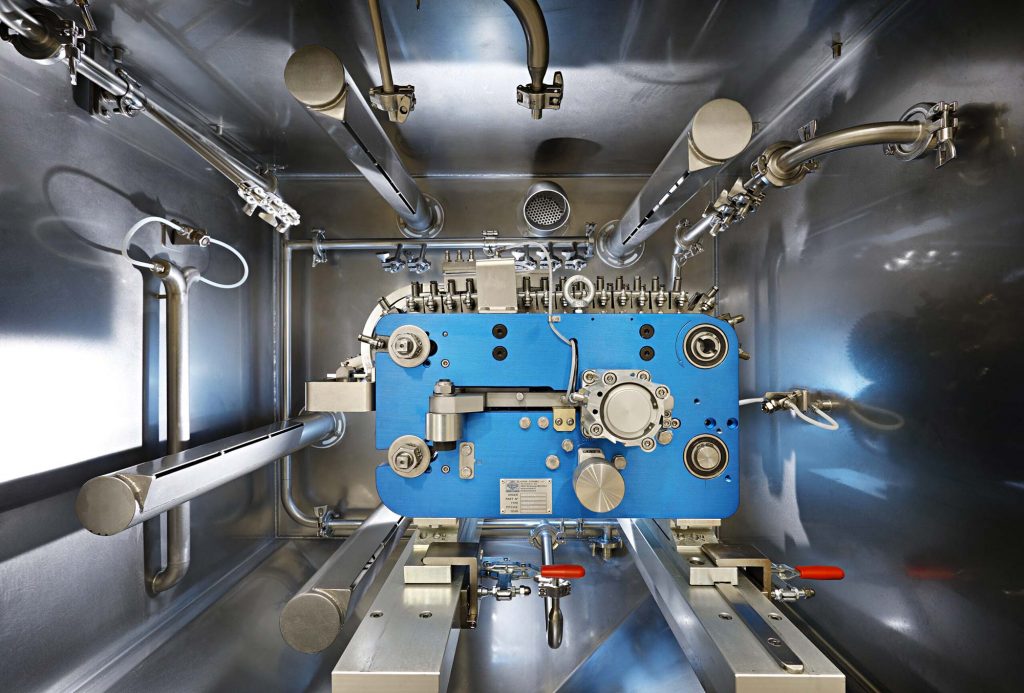

Apollo mini – Chain forming line for hard candy

Apollo mini – Chain forming line for hard candy

The Apollo mini line by Nuova Euromec is the smallest version of the Apollo line, designed for production from 200 to 500 kg/h is a good space saving and budget saving option for small producers or large testing laboratory plants.

It still keeps efficient candy production while ensuring full adaptability to any type of cooking system, whether continuous or batch.

As the whole Nuova Euromec production line portfolio, the line is extremely flexible and keeps fast die set change and high filled product possibility. The main difference between the Apollo is the reduced dimensions of the cooling, as well as dedicated filling pumps.

QUICK FACTS

Application

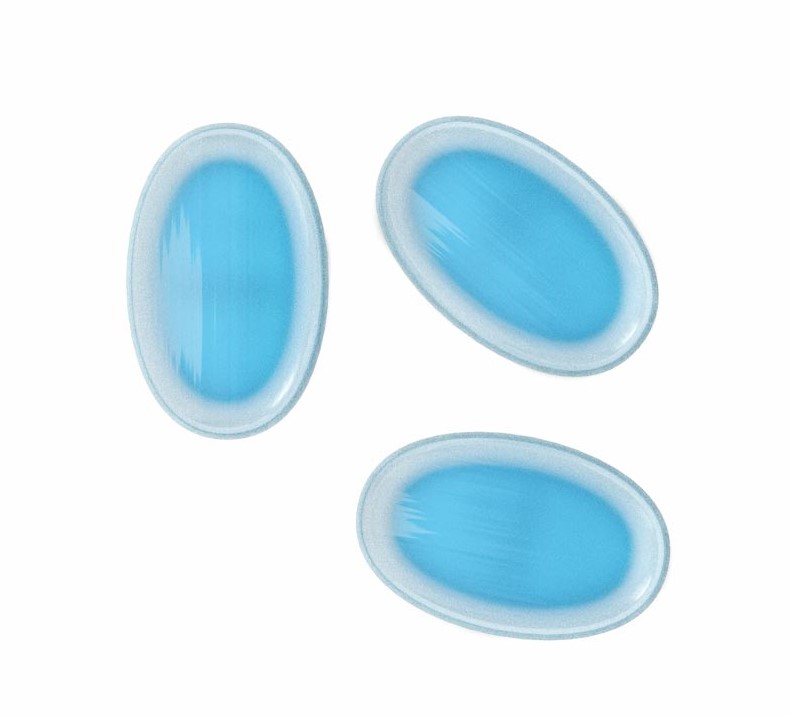

Hard candy

3D Hard candy

High filling percentage hard candy

Lozenges

Medicated candy

Sugar free candy

PRODUCTION SPEED

200-500 kg/h

Filling Options

Liquid

Powder

Gum

Chewy

Color Option

1-4