Production line for laboratories

Production line for laboratories

Nuova Euromec lines can also be designed for laboratory purposes, replicating the same process as full-scale production lines but in a reduced format. With a capacity ranging from 25 to 150 kg/h, these lines guarantee high-quality output while offering significant space savings.

The main purpose of this series is to enable companies to simulate real production conditions, testing masses, flavors, shapes, and line parameters in preparation for a future scale-up to larger production lines. In some cases, thanks to their lower investment compared to full-scale equipment, these lines are also used as primary production units for smaller facilities, ensuring reliability and efficiency with the possibility of future upgrades.

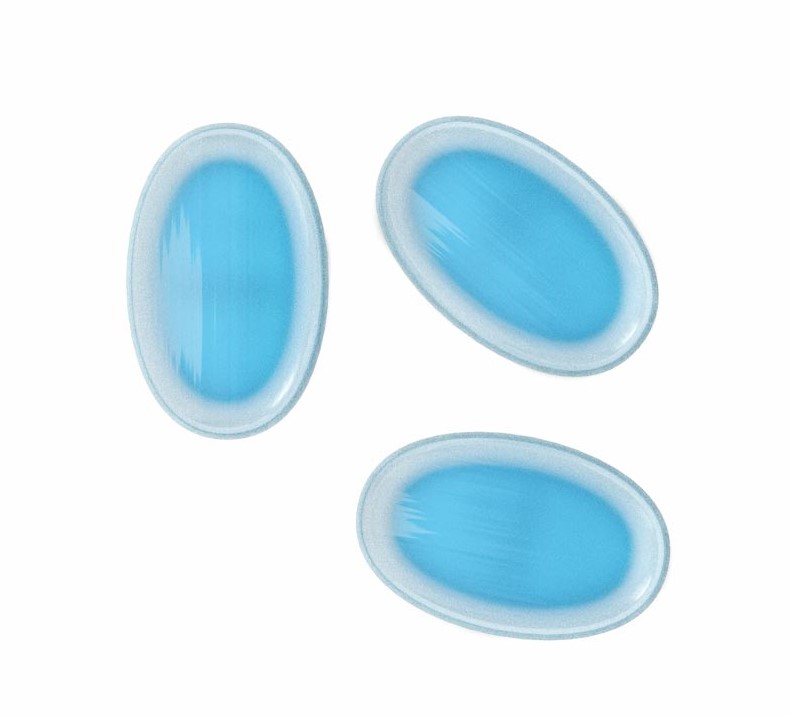

At the heart of our laboratory concept is the modular forming system, built around a chain forming machine compatible with any type of chain die set—for candies, chewy, gum, or lollipops. This versatility allows customers to develop samples and carry out test runs of products not yet part of their portfolio, and then decide whether to scale them up to higher-capacity production.