S37 Center – Drop roller line for chewy candy

S37 Center – Drop roller line for chewy candy

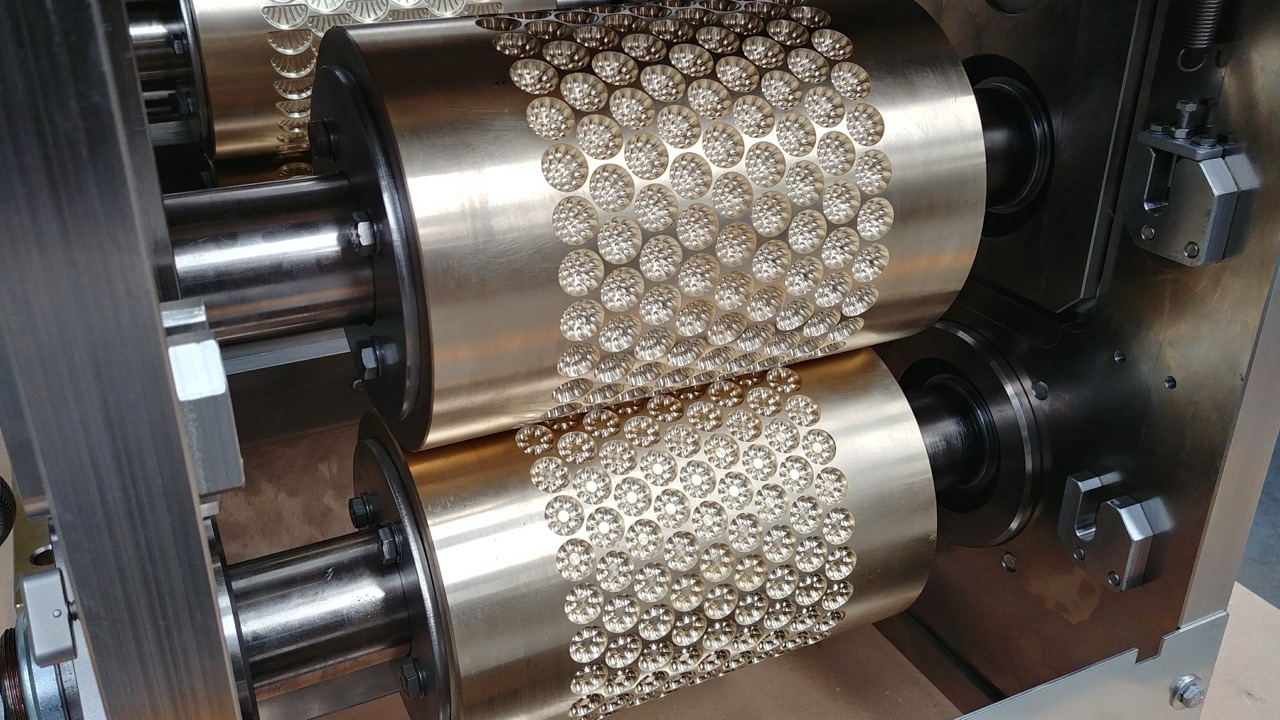

The S37 Center line has been developed to form chewy candies core which will subsequently be coated. Being the core of the forming done with the drop roller technology, the focus of this line is to reduce scraps, ensure consistent product quality, and easy maintenance.

Perfectly suited for products coated in sugar or chocolate, this line is available in three models to match your production needs:

- 300 kg/h for small batches

- 600 kg/h for mid-sized operations

- 1000 kg/h for high-capacity productions.

QUICK FACTS

Application

Chewy candy

PRODUCTION SPEED

300-1000 kg/h PCS/MIN

Color Option

1