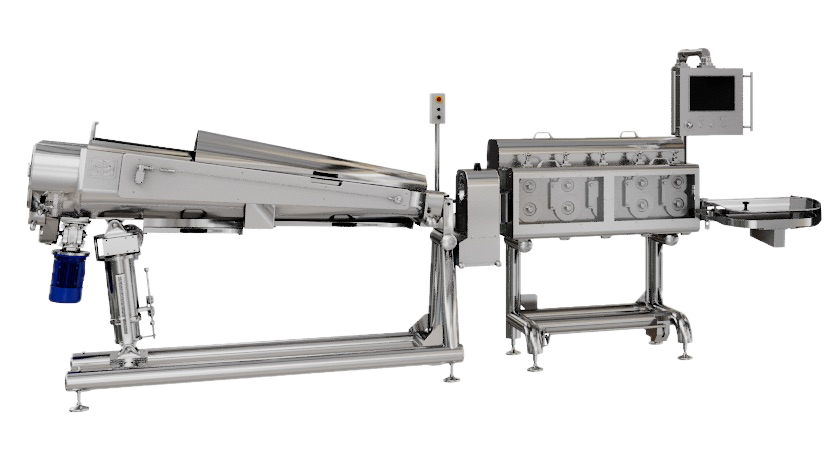

S35 Soft – Cut & wrap line for chewy candy

S35 Soft – Cut & wrap line for chewy candy

This line has been developed to satisfy the request of toffee and chewy toffee candy makers that need a reliable and long lasting solution for their high speed cut& wrapping machines.

As for the rest of our portfolio, it has been constantly optimized and engineered to deliver consistent, efficient candy production while ensuring full adaptability to any type of cooking system, whether continuous or batch, and to adapt to any kind of cut&wrap machine.

QUICK FACTS

Application

Toffe

Mou candy

Soft candy with milk

PRODUCTION SPEED

300-2000 kg/h PCS/MIN

Color Option

1-4