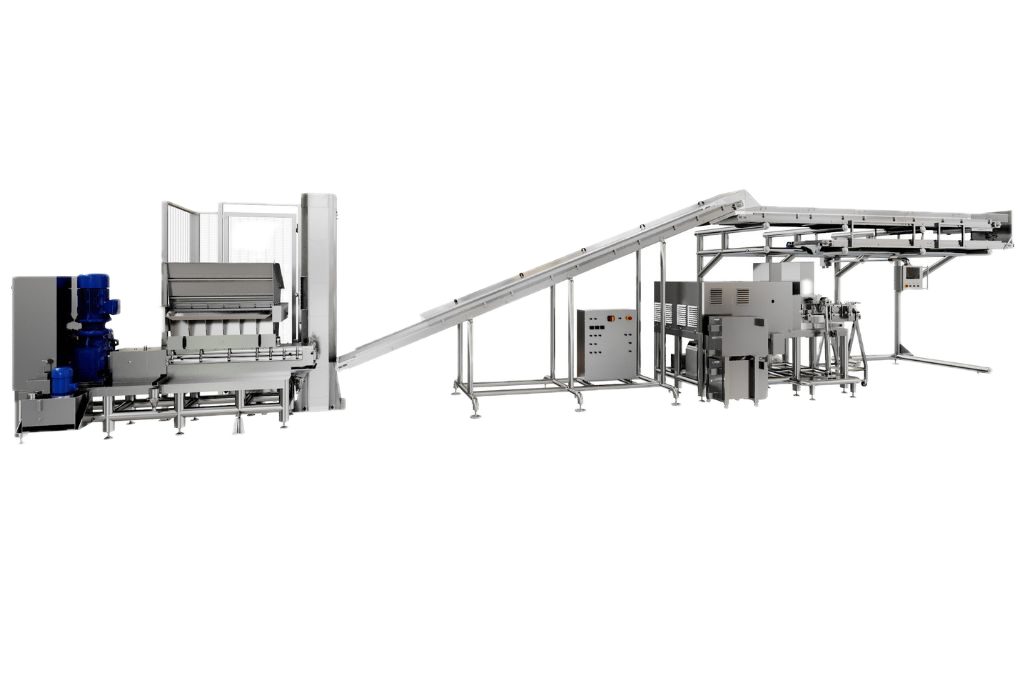

S39 – Rolling & scoring line for chewing gum

S39 – Rolling & scoring line for chewing gum

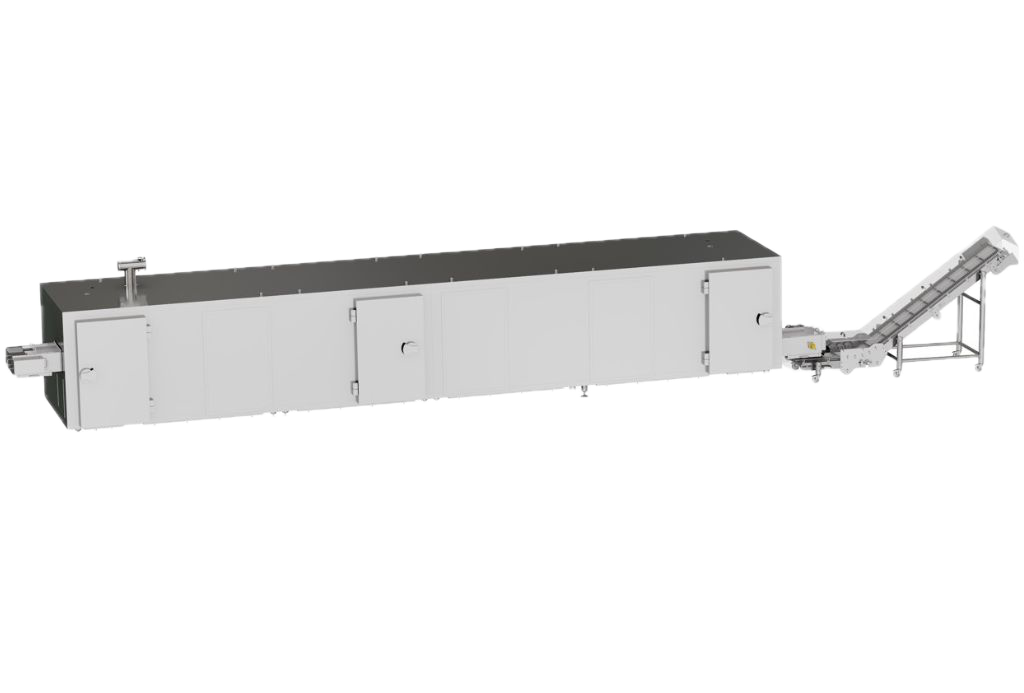

The S39 line is our rolling and scoring solution for the high-capacity production of chiclet and slab gums without filling. Designed for extreme output requirements, it is fully automated through a PLC control system, minimizing the need for manual intervention. Its modular laminating and forming system enables quick and user-friendly changeovers, with each module replaced in less than five minutes.

To overcome the traditional drawback of rolling & scoring lines’ scrap rates, a scrap recovery belt system minimizes waste by reintroducing it directly into the pre-extruder.

QUICK FACTS

Application

Chiclet

Slab

PRODUCTION SPEED

300-1000 kg/h PCS/MIN

Color Option

1