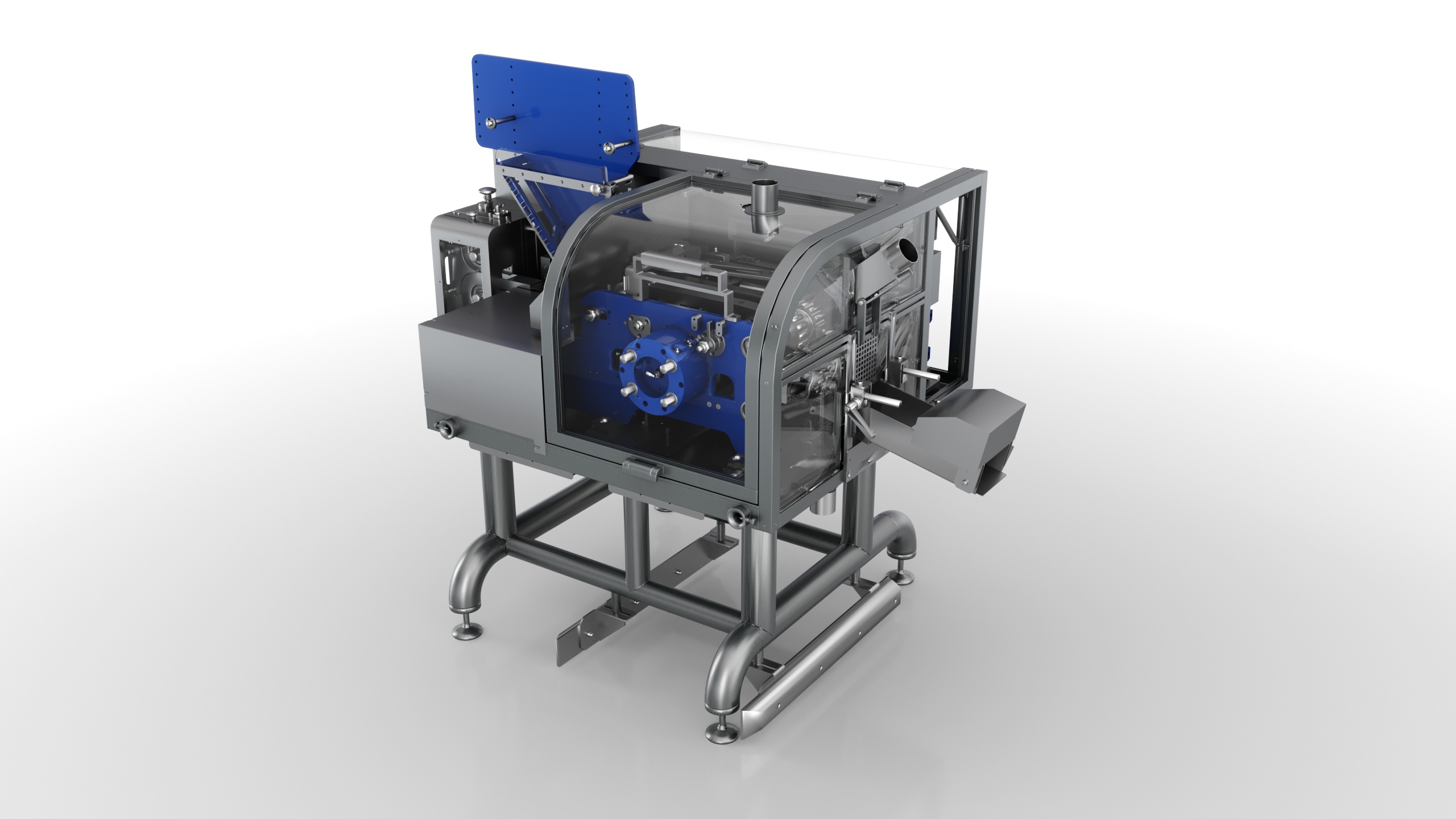

S38 – Lollipop chain former

S38 – Lollipop chain former

The S38 line has been engineered to deliver both high capacity and consistent quality spherical lollipops, reaching production speeds of up to 2,000 pieces per minute while maintaining precise weight and shape control.

Thanks to a die-set changeover time of less than 5 minutes, the it ensures production continuity without variations in product geometry or weight. The line integrates easily with batch and semi-automated cooking systems, offering maximum flexibility across different production environments.

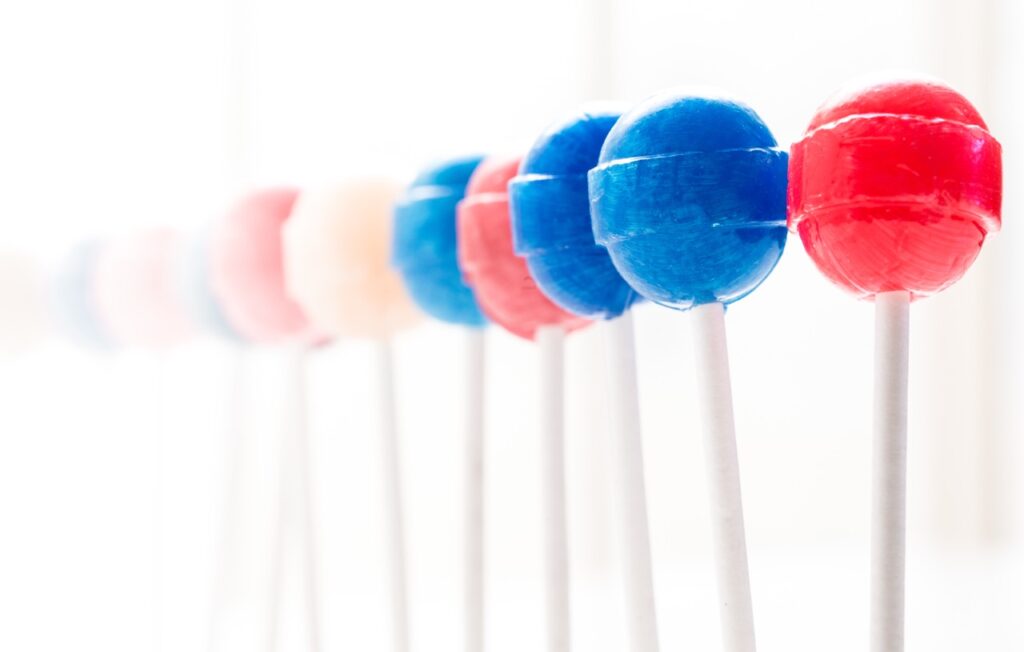

Output can range from simple single color products with one filling to more complex recipes featuring 2, 3, or 4 colors combined with multiple filling types within the same product.

QUICK FACTS

Application

Ball lollipop

Medicated ball lollipop

Ball lollipop sugar free

PRODUCTION SPEED

2200 pcs/min PCS/MIN

Filling Options

Liquid

Powder

Gum

Chewy

Color Option

1-4