Customer Service

Spare parts service

ALWAYS READY – SPARE PARTS WHEN YOU NEED THEM MOST

At Nuova Euromec, we understand how critical it is for your confectionery line to run smoothly without interruptions. That’s why we offer a fast and reliable spare parts service, ensuring you get the components you need, when you need them.

Our forming and processing systems are built with precision, and that same level of care goes into our spare parts support. We keep original components ready for all machine generations, so your equipment can maintain top performance and long-term reliability.

ALWAYS READY – SPARE PARTS WHEN YOU NEED THEM MOST

At Nuova Euromec, we understand how critical it is for your confectionery line to run smoothly without interruptions. That’s why we offer a fast and reliable spare parts service, ensuring you get the components you need, when you need them.

Our forming and processing systems are built with precision, and that same level of care goes into our spare parts support. We keep original components ready for all machine generations, so your equipment can maintain top performance and long-term reliability.

Spare Parts Availability

From soft candies to lollipops and gum, every machine in our portfolio relies on dozens of precision parts.

We maintain a large inventory of key components, which allows us to respond quickly to emergencies, planned maintenance, or upgrades, minimizing downtime and maximizing output.

Expert Spare Parts Support

Need help identifying the right part? Looking to upgrade specific components in your line?

Our experienced engineers are here to guide you — with practical advice, technical insight, and quick support whenever you need it.

In-House Manufacturing Capabilities

Need help identifying the right part? Looking to upgrade specific components in your line?

Our experienced engineers are here to guide you — with practical advice, technical insight, and quick support whenever you need it.

Modernization

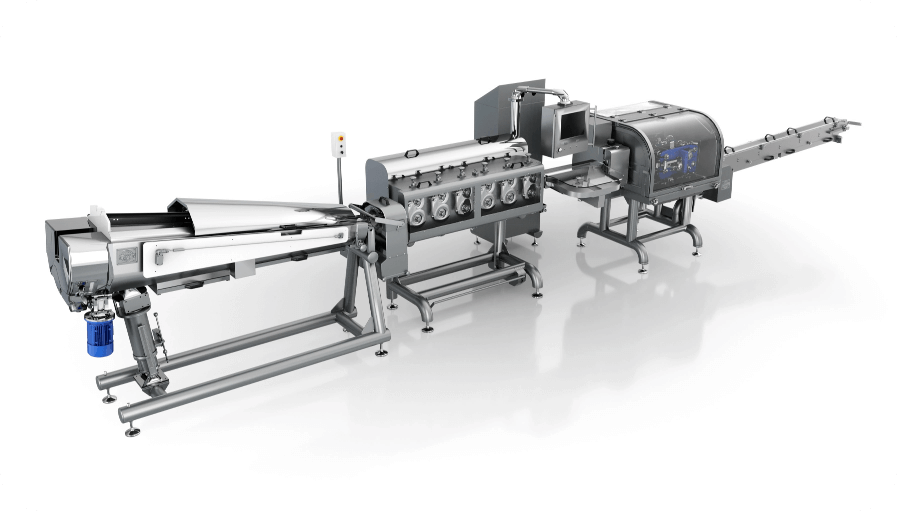

MODERNIZATION – KEEP YOUR LINE FUTURE-READY

Even the best machines benefit from a refresh. After years of reliable service, updating your equipment can bring clear economic advantages, improved efficiency, enhanced safety, and lower operating costs.

If your machine has the Nuova Euromec label, we, as the original equipment manufacturer, offer modernization services in many cases.

At Nuova Euromec, we offer tailored modernization solutions to keep your confectionery line performing at its best. Whether it’s replacing outdated components, upgrading software and safety features, or executing a full mechanical retrofit, we help you bring your system up to today’s standards without starting from scratch.

MODERNIZATION – KEEP YOUR LINE FUTURE-READY

Even the best machines benefit from a refresh. After years of reliable service, updating your equipment can bring clear economic advantages, improved efficiency, enhanced safety, and lower operating costs.

If your machine has the Nuova Euromec label, we, as the original equipment manufacturer, offer modernization services in many cases.

At Nuova Euromec, we offer tailored modernization solutions to keep your confectionery line performing at its best. Whether it’s replacing outdated components, upgrading software and safety features, or executing a full mechanical retrofit, we help you bring your system up to today’s standards without starting from scratch.

Training

TRAINING FOR EVERY TEAM

Every production line is different, and so is every team. That’s why we deliver training built around your specific setup, product type, and goals. Whether you’re producing, we make sure your team has the know how to run the line with confidence.

TRAINING FOR NEW AND EXISTING EQUIPMENT

From day one installation to long time operations, our training covers it all. We help new teams ramp up quickly and support experienced operators with refreshers to boost efficiency, reduce downtime, and extend machine life.

TRAINING FOR EVERY TEAM

Every production line is different, and so is every team. That’s why we deliver training built around your specific setup, product type, and goals. Whether you’re producing, we make sure your team has the know how to run the line with confidence.

TRAINING FOR NEW AND EXISTING EQUIPMENT

From day one installation to long time operations, our training covers it all. We help new teams ramp up quickly and support experienced operators with refreshers to boost efficiency, reduce downtime, and extend machine life.

Remote Assistance

TROUBLESHOOTING

Whatever you’re working on, our technical team is ready to help quickly, reliably, and wherever you are. From complex troubleshooting to simple guidance, our experienced engineers are always on hand to support your operations.

REMOTE ASSISTANCE

Wherever you are, Nuova Euromec is just one connection away. Thanks to a secure remote access system, our technicians can monitor your line in real time, analyze data from PLCs, HMIs, and software, and quickly identify the cause of any stop. Whether it’s troubleshooting an issue, optimizing performance, or guiding your team to safely restart the line — we help you solve it fast.

TROUBLESHOOTING

Whatever you’re working on, our technical team is ready to help quickly, reliably, and wherever you are. From complex troubleshooting to simple guidance, our experienced engineers are always on hand to support your operations.

REMOTE ASSISTANCE

Wherever you are, Nuova Euromec is just one connection away. Thanks to a secure remote access system, our technicians can monitor your line in real time, analyze data from PLCs, HMIs, and software, and quickly identify the cause of any stop. Whether it’s troubleshooting an issue, optimizing performance, or guiding your team to safely restart the line — we help you solve it fast.

Let’s get In touch

Frequently Asked

Questions

";We offer solutions for all scales:

- Smallest batch system: 5–20 kg per batch

- Smallest continuous line: 100 kg/h

- Largest industrial plant: over 2,000 kg/h

Capacities may vary depending on product type, weight and dimensions.

Yes. Our forming lines are modular and can be equipped with custom layouts and accessories to handle:

- Hard or soft candies

- Chewing gum

- Lollipops

All on the same line, with minimal downtime for changeovers.

It depends on your product, production goals, and prior experience.

We offer all three systems, but based on performance and flexibility, we typically recommend chain technology, especially for filled candies.

To define a suitable technical and financial solution, we need:

- Product details: photos, samples or reference specs

- Shape, size, weight and required hourly output (in kg/h)

- Info about existing equipment (mass preparation, cooking system – batch or continuous)

- Type of packaging (flowpack, double twist, etc.)

To run the plant, you’ll need:

- Compressed air

- Water

- Steam

- Electricity

Nuova Euromec specializes in the forming stage – the heart of the process. That’s where our expertise lies, and it’s what made us a trusted reference in the industry for over 70 years.

For complete turn-key solutions, we collaborate with top-tier partners for upstream (cooking) and downstream (wrapping) technologies.

It depends on the filling type. Here’s a general guide (by weight):

- Powder: up to 10%

- Syrup/Pectin base: up to 25%

- Fat-based creams: up to 30%

- Gum/Chewy centers: up to 40%

These values refer to hard candies around 4–5g, produced with chain forming technology.

Not anymore.

Our latest-generation seamless chain die sets now offer a final candy appearance that’s virtually identical to that of rotary systems.

here are three main forming systems:

-

Drop roller system (Cylinder system)

For small-sized candies (under 2g or 12mm), often used to keep a handcrafted look. -

Rotary system

Ideal for solid candies or low-filled products; best for continuous runs with minimal shape variation. -

Chain system

The most flexible solution. Designed for high-speed production of high-quality, center-filled candies. Enables fast product changeovers and higher filling percentages.

Absolutely. Our lab is available to test and develop new recipes or to run FAT trials before final delivery.

This ensures faster installation and smooth product ramp-up. Our experienced technicians can also help fine-tune your process to maximize the line’s performance.

Can you support the development of a new candy product?

In Bergamo, there’s a saying: “All you need is attention, patience… and a little luck.”

Jokes aside, if you’re planning a medium-to-high capacity industrial setup or a small-scale artisanal production, the core components remain the same:

- Mass preparation and cooking system

- Forming line

- Wrapping machines